SUP Quality Inspection

Quality is our strongest commitment - and we've upheld it for over 20 years.

At Ridewave,we adopts a dual quality inspection system (IPOC+OQC) .we have a dedicated in-house QC team that monitors every step of the manufacturing process - from material selection and lamination, to assembly, inflation testing, and packaging.

Our skilled technicians and CAD specialists ensure that every paddle board meets precise specifications.

In addition, each production line is assigned an independent quality inspector to conduct daily checks, ensuring every board that leaves our factory is safe, strong, and ready for your brand.

Double Quality Control System

Ridewave's Double Quality Control System (IPO + OQC)

Built-in Assurance. Independent Confidence.

First Quality Check: IPOC + OQC

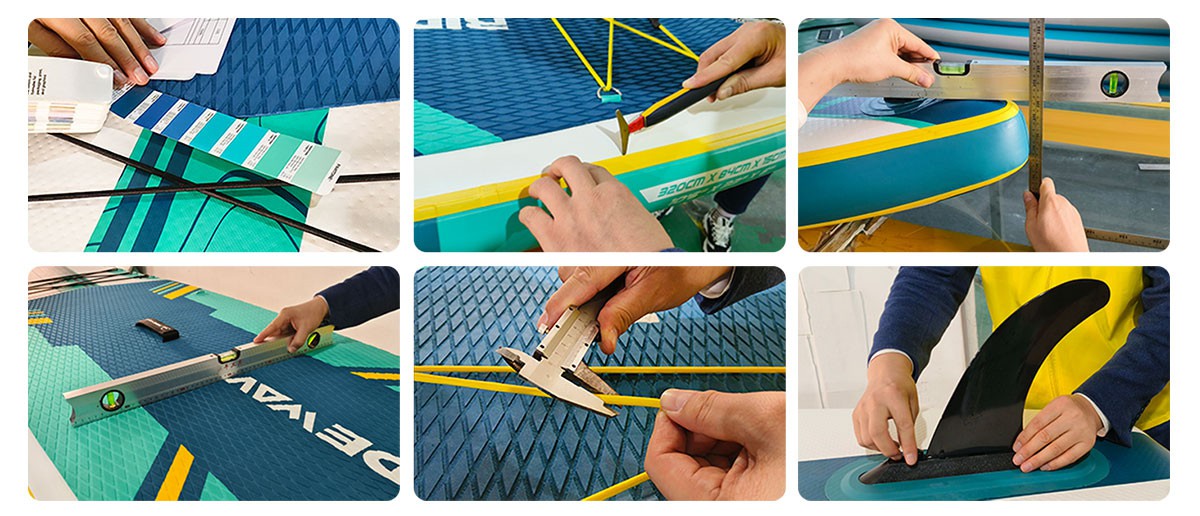

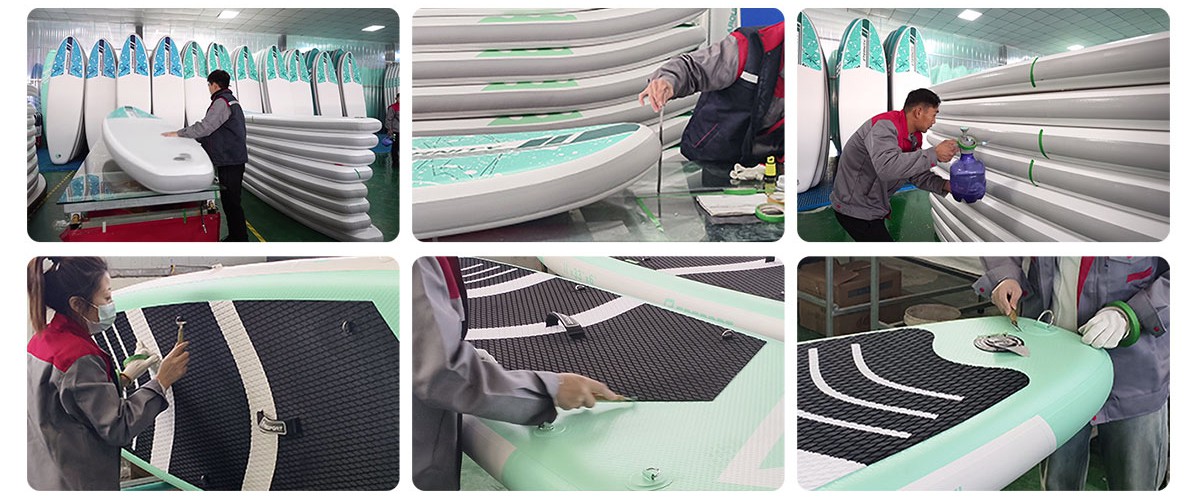

Our in-house QC inspectors monitor every production stage - from material cutting, bonding, lamination, to deck pad application.

All findings are recorded and reported directly to our production headquarters in real time, ensuring immediate correction and full process transparency.

✅ In-Process Quality Control (IPOC)

✅ Outgoing Quality Control (OQC) - Initial review before moving to final inspection

Double Final Check: Independent OQC

Before packaging and shipment, every paddle board undergoes a second full inspection by an independent QC team.

This includes appearance, dimensions, pressure test, valve and fin box inspection, accessory accuracy, and packaging quality.

The final report is submitted directly to the president and sales management for final approval.

🔒 100% QC before packing

📦 Zero-defect policy before delivery