From OEM to Brand Building: How to Launch Your Own Paddle Board Line in 2025 (Part2)

May 10, 2025

Leave a message

In Part 1 of this series, we explored why 2025 is the ideal year to launch your own paddle board brand, how to identify the right market niche, and how to choose a reliable OEM manufacturer in China. But finding your supplier is just the beginning.

Now it's time to shape your vision into a real, sellable product.

In Part 2, we'll walk you through the creative and strategic steps that turn a generic OEM board into a branded product that speaks to your target audience. You'll learn how to:

Customize your paddle board design and add market-driven features,

Build a strong brand identity through logo, packaging, and storytelling,

Understand the production process and ensure quality control from your factory partner.

Whether you're a wholesaler, distributor, or launching your own DTC brand, these steps are critical for creating paddle boards that not only perform well-but sell well, too.

Let's dive in.

Step 3: Develop Your Own Paddle Board Design and Features

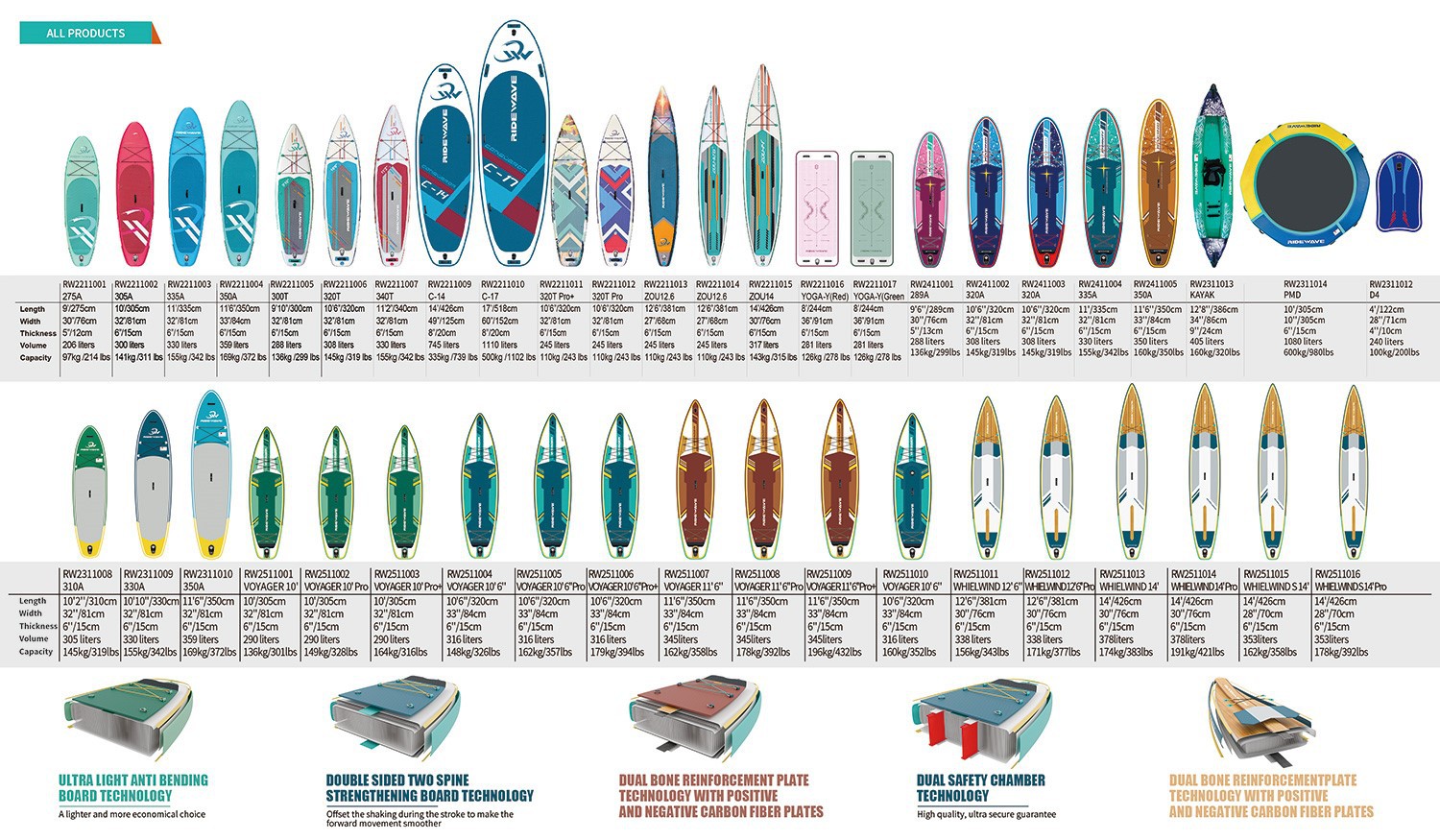

1. Choose the Right Paddle Board Shape and Size

Your board's shape determines performance, so base it on your niche market:

All-around SUPs (10'6", 32"): Best-selling for beginners, family, and casual use

Touring SUPs (11'–12'6", narrower widths): Popular in Europe for long-distance lake and river paddling

Surf SUPs (under 9'6"): Ideal for Australian brands targeting beach and wave riders

Yoga SUPs (33"–35" wide): For wellness-focused customers, often in resort settings

Racing SUPs (12'6"+, narrow): For performance-oriented markets

🎯 RIDEWAVE can advise on the top-selling dimensions per region and support new brand owners with ready-to-customize templates.

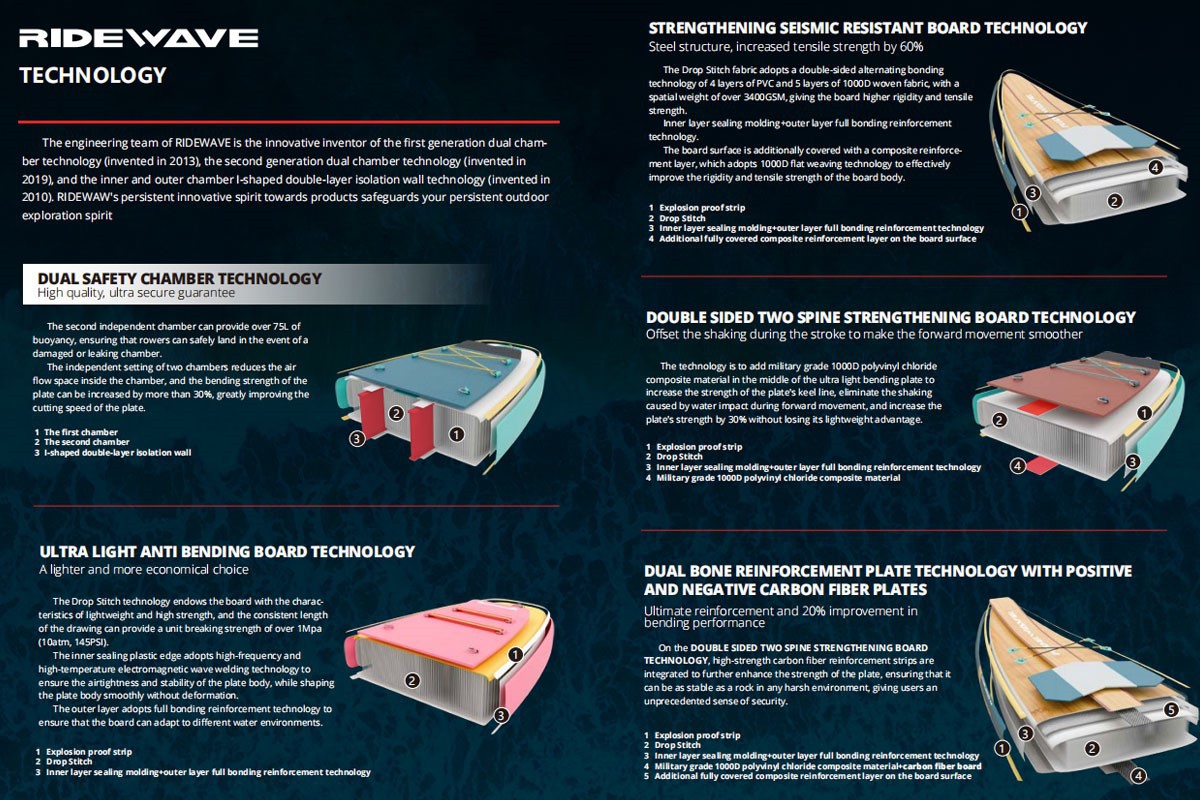

2. Pick the Right Construction Paddle Board Technology

Your customers care about weight, durability, and stiffness. Common inflatable SUP construction types include:

Single-layer PVC: Light and cost-effective, good for price-sensitive markets

Double-layer PVC (manual or fusion): Stronger, stiffer, more premium feel

Woven drop-stitch + carbon side rails: High-performance construction for pros and racers

Choose construction that matches your brand promise-whether that's affordable fun or elite performance.

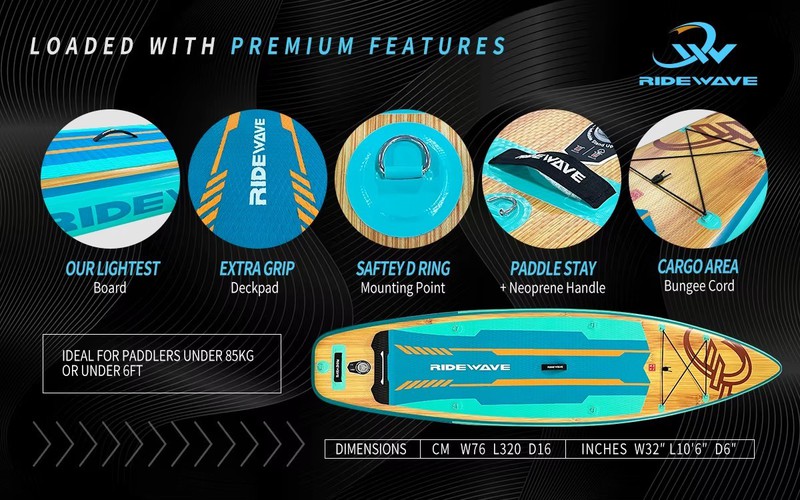

3. Paddle Board Design Custom Features and Accessories

Adding the right functional details will boost perceived value:

EVA deck pad: Choose textures and colors (crocodile skin, diamond groove)

Bungee cords: Front, rear, or both for storage flexibility

Camera mounts / D-rings: Add-ons for adventure seekers or yoga straps

Inflation valves & fin systems: Choose US fin boxes or snap-in systems for easy use

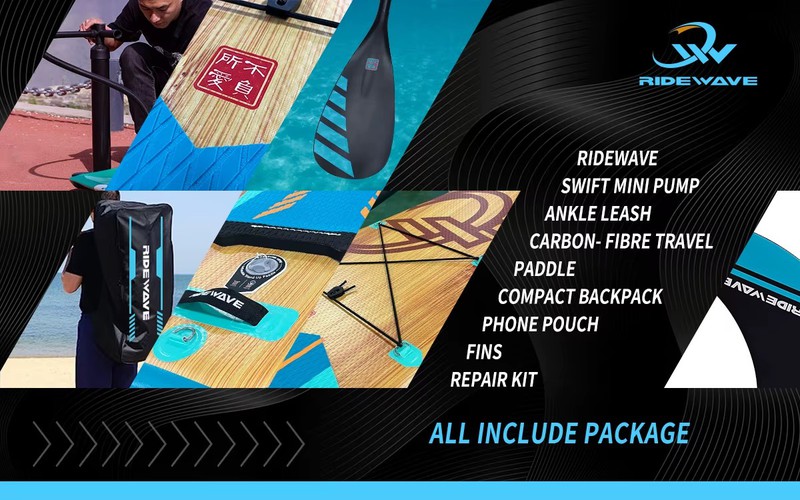

Custom paddle, leash, pump, and backpack: Consistent branding across accessories

🔧 RIDEWAVE supports full accessory customization-from printing your logo on paddles to designing eco-friendly packaging.

4. Paddle Board Visual Design – Make It Eye-Catching

Your board's graphic design should reflect your brand personality. Consider:

Bold, colorful designs for younger or lifestyle-focused markets

Minimal, elegant lines for premium or eco-friendly brands

Regional cultural elements for local appeal (e.g. Russian art motifs, Australian wildlife themes)

RIDEWAVE offers in-house design assistance, or we can work with your designer to prepare print-ready files (in AI or PDF format).

5. Paddle Board Test and Optimize Before Mass Production

Before full production, always test your prototype:

Does it feel stable and stiff enough on water?

Are accessories durable and easy to use?

Is your logo placement clean and visible?

Do colors and print details match your brand guide?

Collect early feedback from distributors or local testers-then optimize before scaling up.

📦 At RIDEWAVE, we provide sample production and small batch orders, helping new brands minimize risk and refine their designs.

Step 4: Paddle Board Branding Essentials – Logo, Packaging, and Storytelling

Paddle Board Brand Building

1. Create a Professional Logo that Speaks Your Brand

Reflect your target market (youthful, eco, adventurous, luxury, etc.)

Work well on all surfaces: board, paddle, backpack, website, catalog

Be vector-based for easy printing (AI, EPS, PDF)

Stay readable in both full color and monochrome

2. Design Packaging That Adds Value

Packaging matters-especially for retail display, Amazon sales, and first impressions with distributors. Don't just use a plain box. Consider:

Full-color printed cartons with your logo and product photos

Custom-designed backpacks or trolleys with embroidered or silk-screen branding

Printed user manuals with setup instructions, safety tips, and warranty

Eco-friendly packaging for sustainable branding

3. Develop a Strong Brand Story

Modern customers don't just buy products-they buy into a story. Your brand narrative can help distributors and end customers emotionally connect with your paddle boards. A good brand story usually includes:

Why you started the brand (passion for SUP, travel, wellness, etc.)

What makes your boards unique (materials, community, purpose)

Who it's for (adventurers, families, athletes, eco-conscious users)

Your brand values (freedom, sustainability, innovation…)

How to Ensure Visual Consistency Across All Touchpoints for Your Paddle Board Brand

To build trust in your brand, your visual identity must stay consistent:

Use the same logo size and placement across products

Stick to a defined color palette and font set

Create a brand style guide for your team or marketing partners

Align product photos, social media, and packaging with your identity

RIDEWAVE can help you build a brand asset library (including PSD mockups and photography templates) that matches your board and accessories.

Register Your Paddle Board Brand: An Optional Yet Smart Step

If you're planning to scale, register your brand name and logo in:

Your home country (EU IPO, UK IPO, IP Australia, or Rospatent in Russia)

Key e-commerce platforms (like Amazon Brand Registry)

Optionally, in China for IP protection during manufacturing

This step protects your investment and avoids copycats or name conflicts.

Step 5: Paddle Board Quality Control – What to Expect from the Factory

1. Understand the Paddle Board Production Process

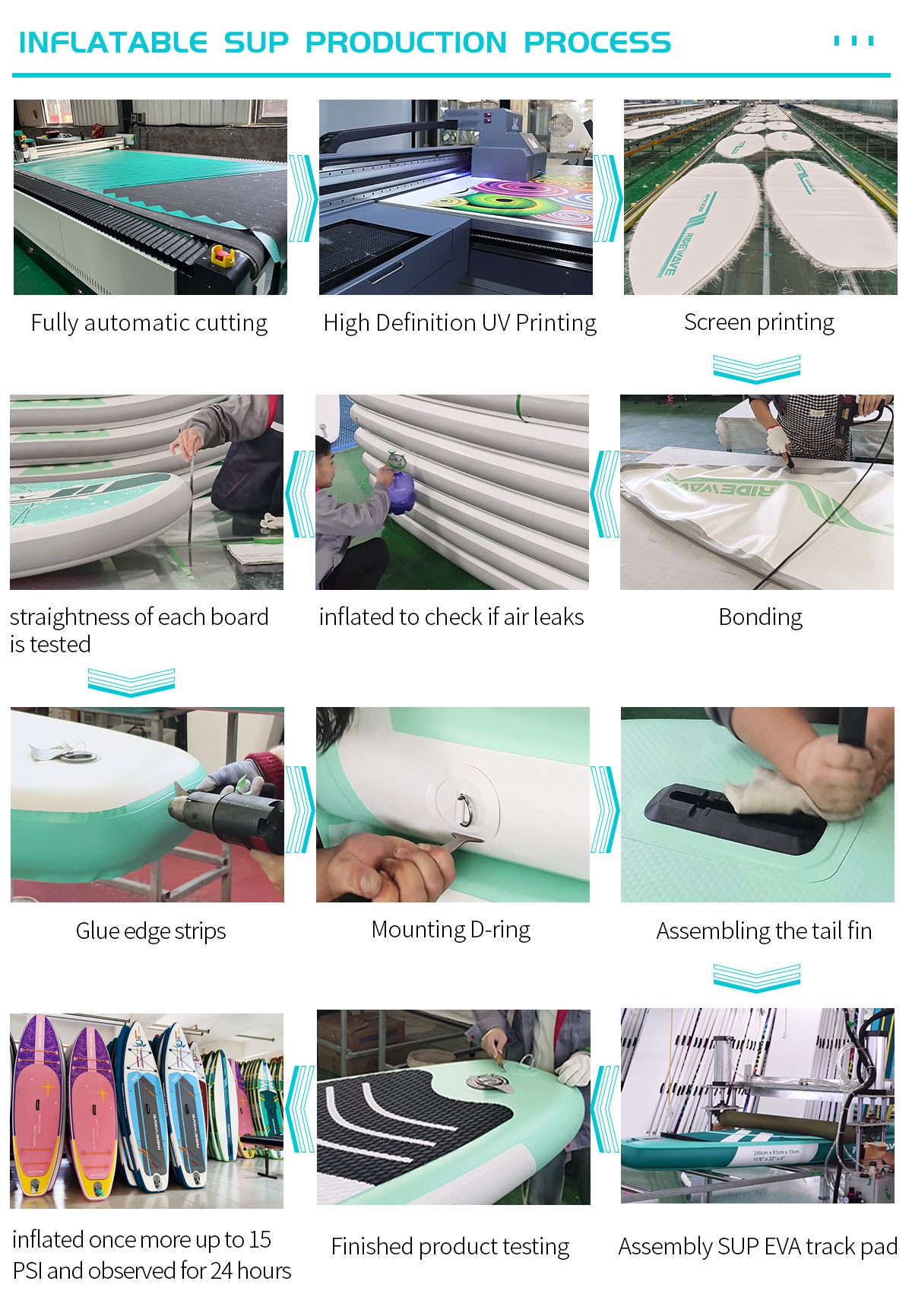

Here's a simplified breakdown of how inflatable SUP boards are manufactured in a good OEM factory:

Material Cutting – PVC fabric and drop-stitch cores are cut using CNC precision

Printing & Lamination – Your custom design and logos are printed and heat-laminated

Assembly – Panels are glued or welded together, and EVA pads, handles, fins, valves are installed

Inflation Testing – Every board is inflated to full PSI (usually 15–20) and left for 48 hours to detect leaks

Cleaning & Packing – Boards are cleaned, inspected, and packed with all accessories

⚙️ RIDEWAVE provides real-time photo/video updates during production for full transparency.

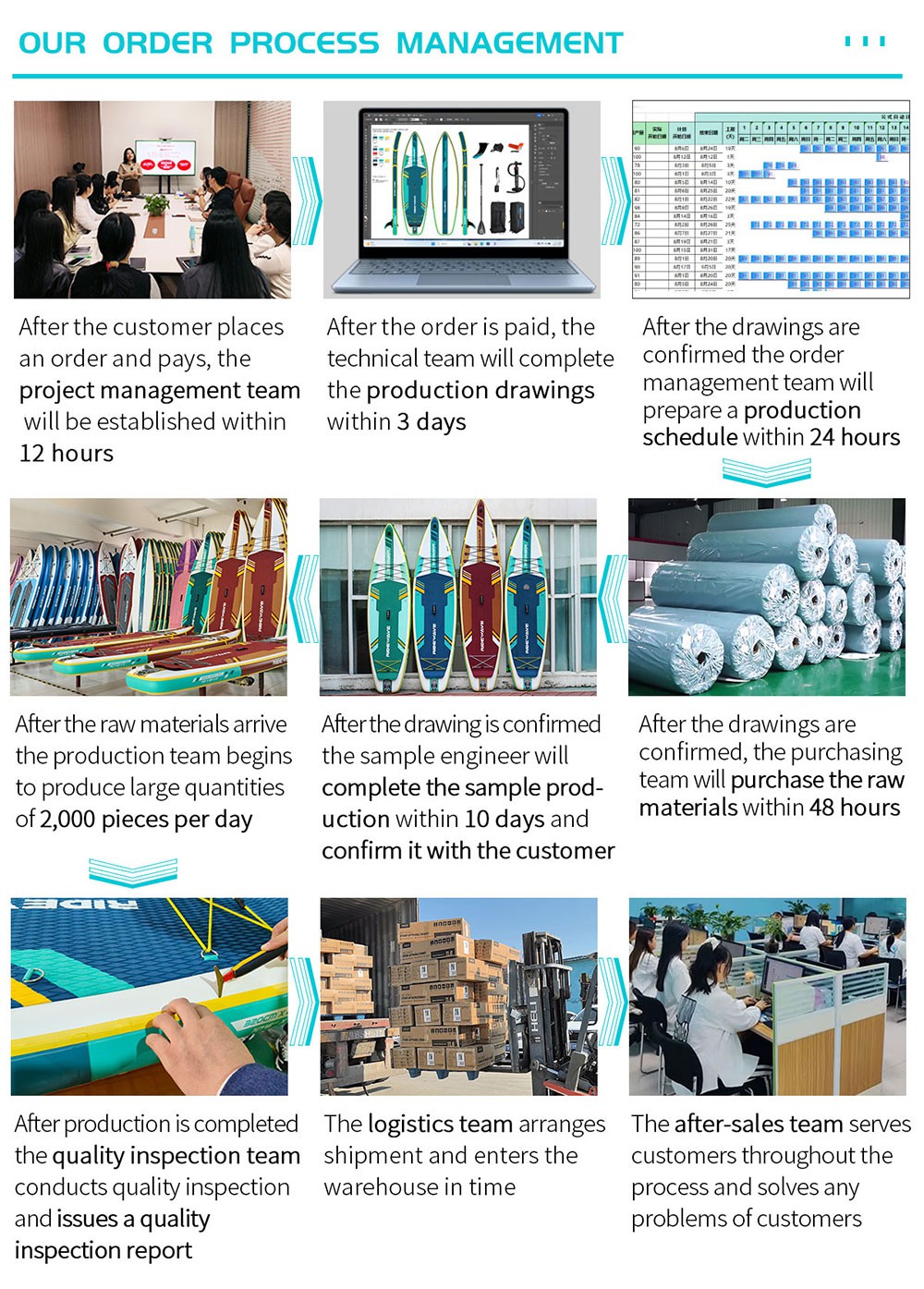

2. Set Clear Production Expectations Before Starting Your Paddle Board Order

To avoid delays or surprises, confirm the following before placing your bulk order:

MOQ (Minimum Order Quantity) – Standard is 50–100 units, but RIDEWAVE offers flexible MOQs for new brands

Lead Time – Usually 25–40 days depending on season and order volume

Materials & Components – Confirm what PVC, drop-stitch, EVA foam, valves, and accessories will be used

Print File Format – Make sure your designs are in AI or PDF with all fonts outlined

Labeling – Decide if you want barcode stickers, QR codes, serial numbers, etc.

📋 At RIDEWAVE, we issue a clear order sheet with all specifications before production begins-ensuring you stay in control.

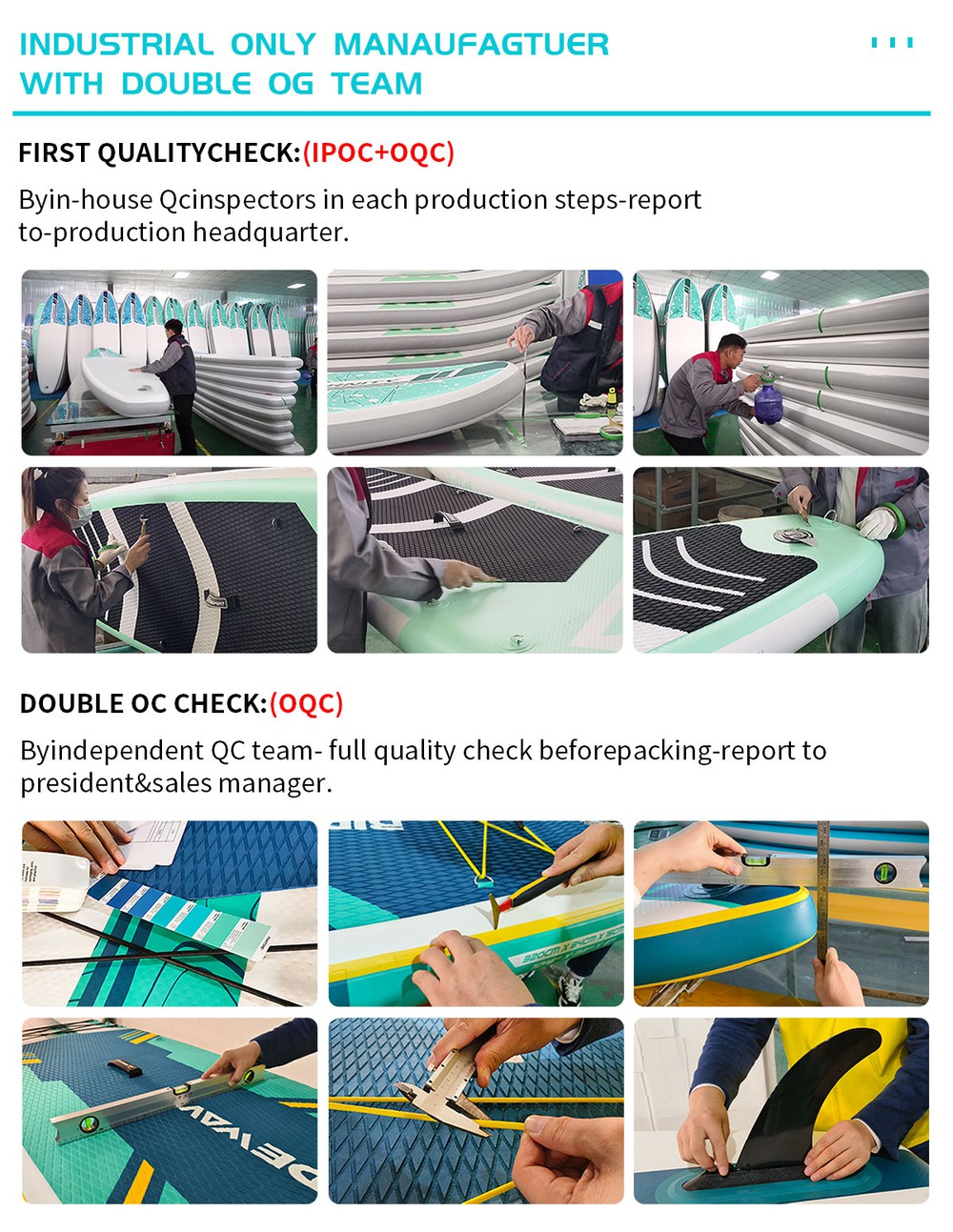

3. Paddle Board Quality Control – What Checks Should Be Done

High-quality paddle boards require multiple QC checkpoints. You or your supplier should cover:

✅ Raw material inspection

✅ Pre-assembly check (print quality, EVA alignment, parts)

✅ Inflation test (48 hours at full pressure)

✅ Final surface check (air leaks, glue marks, dirt, logo clarity)

✅ Accessory testing (zippers, straps, pumps, paddles, etc.)

If you're not onsite, ask for detailed QC reports with photos or videos.

🔍 RIDEWAVE's in-house QC team follows strict protocols and shares reports with every shipment. We also welcome third-party inspections (SGS, TÜV, etc.)

4. Paddle Board Sampling & Pre-Shipment Inspection

Before mass production, it's smart to order a pre-production sample to:

Verify design accuracy

Test product quality in your local water conditions

Show your distributors or test with influencers

Make last-minute tweaks before the bulk order

Once production is done, you or a trusted QC agent should conduct a pre-shipment inspection to verify quality, quantity, and packaging.

📦 RIDEWAVE offers fast sample production (7–10 days) and free sample revisions if issues are caused on our side.

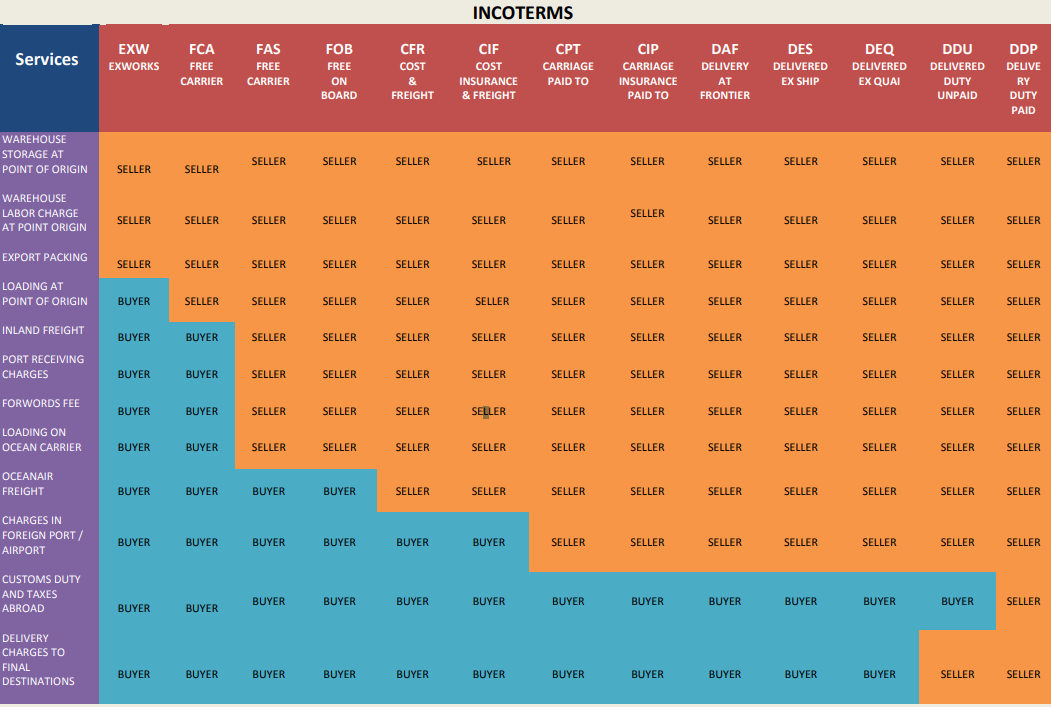

5. Smooth Paddle Board Launch Starts with Smart Logistics Planning

After QC, your boards need to be shipped efficiently. Options include:

Sea freight (FCL or LCL) – Best for large B2B orders; takes 20–40 days

Rail freight – Faster than sea for Europe (10–18 days via China–Europe train)

Air freight – Expensive, but fast for urgent samples or small launches

RIDEWAVE can assist with EXW, FOB, or DDP delivery terms, helping you find the best balance of cost and time.

You've Paddle Board brand Built It-Now Let's Sell It: Preview of Part 3

Bringing your paddle board vision to life-from choosing the right design to ensuring production quality-is a major milestone. But even the best product won't succeed without smart market entry strategies.

In Part 3 of this series, we'll guide you through the next phase:

how to launch your paddle board brand into the market. You'll learn how to price your products, find the right sales channels (online and offline), approach distributors and retailers, and run marketing campaigns that attract loyal customers-especially in competitive markets like Europe, Australia, and Russia.

👉 Stay tuned for Part 3: "From OEM to Brand Building – How to Launch Your Own Paddle Board Line in 2025" – where we turn your finished product into a market success.

|

Final Section: Related Articles You May Like

|

| Each post explores the challenges and best practices B2B buyers face in a specific area-don't miss them! |